Industrial Machines: Key Roles In Modern Manufacturing Processes

Outline

– Introduction: why machines matter now in cost, quality, flexibility, and speed.

– Core machine types and how they turn material into finished goods, with practical examples.

– Automation and control systems that coordinate motion, inspection, and flow.

– Energy, maintenance, and reliability practices that keep assets productive.

– Digital thread from design to execution, and how data improves outcomes.

– Safety, skills, and sustainability shaping the future of machine-centric operations.

– Conclusion for decision-makers: how to prioritize investments and de-risk adoption.

Introduction: Why Industrial Machines Still Set the Pace

Walk through any factory and you’ll feel a pulse: spindles hum, presses thump, conveyors whisper. That rhythm is the choreography of industrial machines converting ideas into tangible goods, hour after hour. In a landscape defined by shorter product cycles, volatile supply chains, and rising quality expectations, the equipment you choose—and how you run it—decides more than throughput. It influences unit cost, scrap, energy use, worker safety, customer lead time, and even the brand reputation attached to every shipment leaving the dock.

Today’s manufacturing leaders are asked to do more with less: more mix, less margin; more traceability, fewer surprises. Machines carry that load when they’re specified, integrated, and maintained with purpose. The payoff is measurable. Facilities that align machine capability with demand often report first-pass yield improvements, narrower tolerance bands, and steadier takt times. World-class benchmarks set Overall Equipment Effectiveness targets near the mid-80% range, while many plants still live between 40–60%, signaling a wide lane for improvement without adding square footage or headcount.

But this isn’t simply a race for faster spindles or heavier presses. It’s about systems thinking: how cutting and forming synchronize, how sensors see what humans miss, how software guides motion, and how energy and maintenance shape total cost of ownership across a decade or more. In the pages that follow, we map the roles machines play—from metal and polymer transformation to automation and data—and translate those roles into practical choices you can act on this quarter.

From Raw Material to Finished Goods: Core Machine Types and Their Roles

Every product story starts with matter changing shape. Subtractive, formative, additive, and joining machines are the principal actors in that transformation. Subtractive equipment—mills, lathes, grinders—removes material to reveal geometry with tight tolerances. In precision work, holding ±0.01 mm is common on stable setups, while specialized grinding and honing go tighter still. Formative machines—press brakes, stamping presses, roll formers, extrusion lines—reshape stock economically, yielding high volume at low variable cost once tooling is dialed in. Molding and casting machines—whether injection, compression, blow, or die casting—create net or near-net shapes that demand careful thermal control to limit residual stress and porosity. Additive systems build up layers, unlocking internal channels, lattices, and rapid tool-less changeovers that would be impractical or impossible subtractively.

Comparisons matter. Subtractive excels in surface finish and tight tolerances but often wastes material; additive conserves feedstock and speeds iteration, yet may need post-processing for surface or mechanical properties. Forming achieves extraordinary cycle times—stamping lines routinely deliver parts in seconds—but relies on upfront tooling and steady demand to justify the setup. Molding sits in the middle: cycle times measured in tens of seconds with well-controlled repeatability, as long as temperatures, pressures, and venting are consistent. In practice, most factories mix these modes. A bracket could be stamped, tapped on a machining center, welded to a subassembly, then powder-coated, each machine adding value, each with its own definition of “done right.”

To visualize value flow, think in station-level metrics: takt time, changeover time, scrap rate, first-pass yield, and OEE. A machining cell might clock a 90-second cycle, 8-minute tool changes, and a 2% scrap rate driven by tool wear. A molding press could run a 30-second cycle with cavity pressure monitoring trimming scrap under 1%. A forming line might blaze through coils faster than downstream deburring can keep up, shifting the constraint to finishing. The trick is matching machine class to the product’s design-for-manufacture envelope:

– Subtractive for precision faces, holes, and hard alloys.

– Forming for high-volume geometry with repeatable bends or draws.

– Molding/casting for complex 3D shapes in polymers or light metals.

– Additive for rapid iteration, conformal cooling, and lightweight topology.

– Joining and finishing to consolidate components and protect surfaces.

When you align machine capability with the right materials and volumes, you not only raise throughput but also tame variability. That reduces hidden costs—rework, overtime, expediting—that quietly erode margins even when headline cycle times look heroic.

Automation, Robotics, and Control Systems: Orchestrating Precision

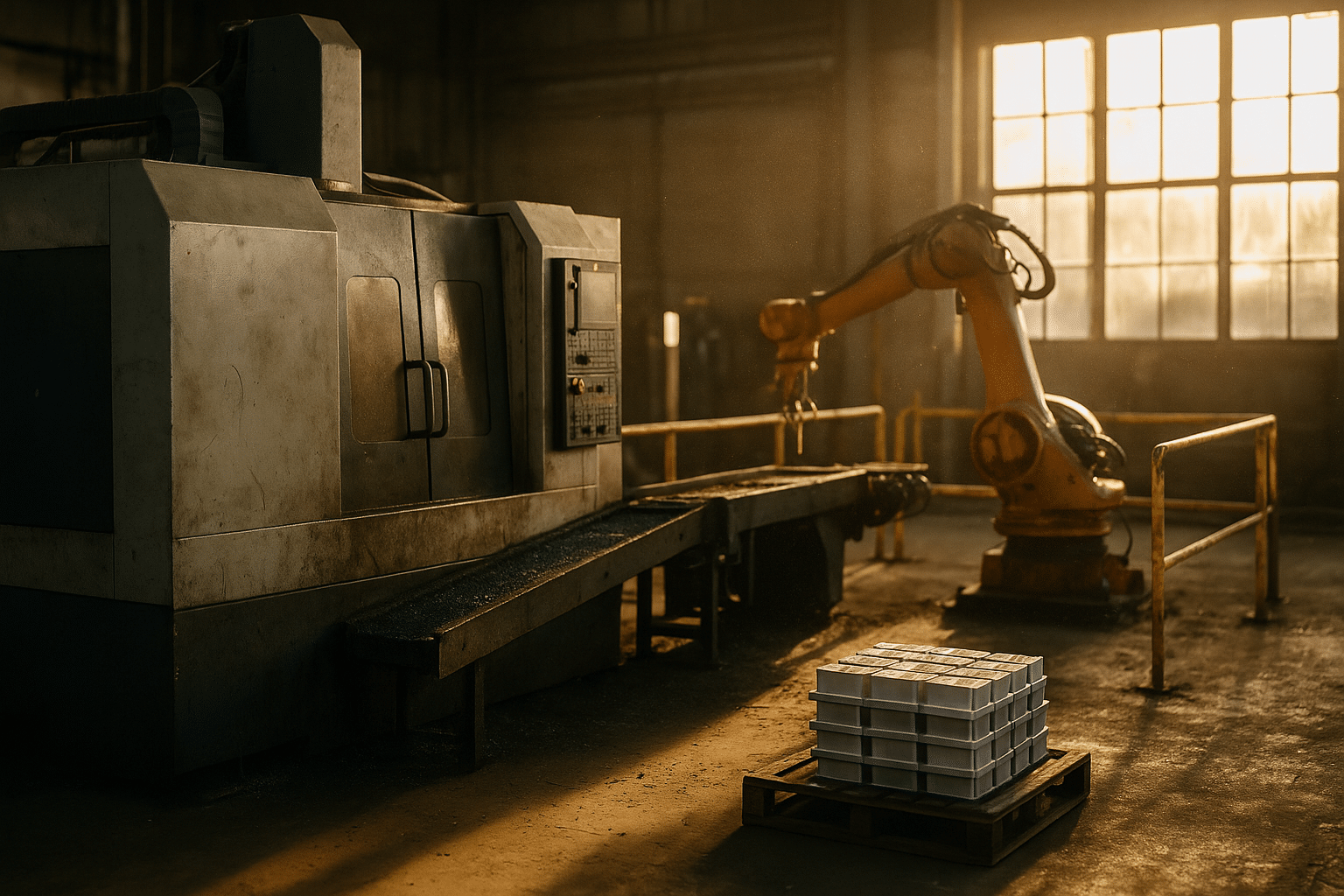

Automation turns individual machines into an ensemble. Programmable logic controllers, motion controllers, and feedback loops coordinate actuators with sensors so parts arrive, clamp, cut, and pass inspection in a single flow. Vision systems catch burrs, flash, or dimensional drift before a pallet moves on. Servo axes interpolate arcs and helical paths so finishes gleam without sanding. And robotic arms handle the dull, dirty, and dangerous—loading raw stock, tending furnaces, or palletizing cartons—at steady tempos that humans understandably cannot sustain shift after shift.

Scale underscores impact. Industry reports indicate that annual industrial robot installations now exceed half a million units worldwide, a signal that repetitive handling and arc welding are being automated at pace. Density varies by sector; electronics and transportation clusters often deploy hundreds of robots per 10,000 employees, while job shops adopt more selectively. Yet even light automation can unlock meaningful gains. A two-machine tending robot may lift utilization by double digits simply by shrinking idle time between cycles and enabling small, consistent buffers that smooth flow.

Control strategy is a major lever. Centralized control eases synchronization across a line but can be brittle if one station fails; distributed control keeps cells resilient, letting upstream and downstream continue in a degraded yet productive mode. Deterministic field communication reduces jitter so inspection cameras and cutters remain in lockstep. Add part tracking—through codes or embedded devices—and you can route exceptions intelligently: a part failing a torque test diverts to rework without halting the main path. Compared with manual handoffs, this orchestration shrinks variation in cycle-to-cycle timing, which is the difference between a plan that fits on paper and a plan that ships on time.

Practical choices start with the constraint. If the bottleneck is spindle time, automate loading and measurement; if it’s inspection, add in-line gauging; if it’s changeover, design quick-release tooling and recipes that load parameters reliably. Safety is not negotiable—interlocked doors, presence sensing, and rated guards must be built into motion plans from day one. When automation is scoped to the real constraint, it pays back faster, avoids overbuilding, and earns trust on the floor.

Energy, Maintenance, and Reliability: Keeping Machines Productive

Electric motors power much of manufacturing’s heartbeat, and industry accounts for roughly a third of global final energy use. That makes energy management a strategic lever, not just a utility bill. Variable-speed control on pumps and fans often trims consumption by double digits because cubes and squares govern fluid power; slowing a blower a bit can deliver outsized savings. Heat recovery from ovens or compressors pre-warms process air. Leak hunts on compressed air systems reclaim capacity—plants routinely find 20–30% losses hiding in fittings and hoses. These wins compound with maintenance discipline, stretching both uptime and asset life while cutting kilowatt-hours per unit shipped.

Maintenance strategy shapes outcomes. Run-to-failure fits low-criticality assets but invites chaos on constraint machines. Time-based preventive maintenance trades a bit of over-service for predictability, ideal where failure modes correlate with age or cycles. Predictive and condition-based programs sit at the frontier: vibration spectra catch unbalance and bearing wear; thermography reveals electrical hotspots; oil analysis flags contamination and wear metals; acoustic monitoring hears cavitation before humans do. Studies commonly cite maintenance cost reductions in the teens to thirties percent range, alongside meaningful drops in unplanned downtime, when condition data guides interventions.

Reliability engineering converts anecdotes into math. Failure modes and effects analysis prioritizes what can go wrong and how badly; root cause analysis prevents déjà vu failures; spare parts strategies balance carrying cost with service levels. The metric stack—mean time between failures, mean time to repair, and planned maintenance percentage—keeps teams honest about whether reliability is improving or merely being rescheduled. Compare two identical presses: one with disciplined lubrication, aligned tooling, and a clean power supply; another with irregular oil, hard hits, and dirty power. Over a year, the first usually logs higher OEE, lower scrap, and calmer shifts, even if nameplate specs match.

Practical, low-friction steps work well:

– Instrument the constraint asset first; trend a few variables rather than logging everything.

– Standardize work for cleaning, inspection, and lubrication to create early warning senses.

– Tie energy meters to production counts to expose energy per good unit, not per hour.

– Create a short “first-response playbook” so operators can fix the top three chronic stoppages.

In reliability, as in quality, small, repeatable wins build confidence, and confidence unlocks bigger bets like full predictive programs or energy retrofits across the fleet.

The Digital Thread: From Design to Shop-Floor Execution

Modern machines do more than move metal or mold plastic; they speak data. The “digital thread” connects design, planning, machining, inspection, and delivery so the version on paper matches the version on the pallet. Computer-aided design feeds manufacturing instructions that generate toolpaths or forming recipes. Manufacturing execution systems dispatch work, capture parameters, and reconcile counts. Quality systems record measurements against tolerances in real time. When a drawing change lands, the thread pushes updated parameters to the right cells and blocks obsolete variants from sneaking into production.

Benefits accumulate at handoffs. Offline programming reduces setup time while cutting first-article iterations. Digital work instructions lower training time and variance in manual steps. In-line metrology writes numbers directly to records, shrinking keystroke errors and letting control charts react before defects multiply. Plants that digitize travelers and capture machine states often report:

– Shorter changeovers thanks to parameter libraries and fixture recall.

– Fewer stockouts as consumption signals pull material just in time.

– Faster root cause analysis, since traceability ties a bad reading to a specific lot, tool, or shift.

– Clearer capacity planning because data shows true cycle times instead of estimates.

Still, there are pitfalls. Data without context creates noise; too many dashboards dilute attention. Latency matters—if a signal arrives minutes late, you’re reacting to the past. Cyber risk grows with connectivity, demanding segmented networks and access discipline. And culture is decisive: if frontline teams don’t trust the numbers, the thread frays. The remedy is incrementalism. Start with one product family, map the information flow, and close two or three glaring gaps—perhaps automated parameter loading and scanned part IDs at the constraint. Prove the value in scrap avoided and hours saved. Then scale to adjacent cells, always keeping the feedback loop tight so the system serves the work, not the other way around.

When the digital thread runs end to end, machines act with context. A mill loads the right offsets for a material lot. A welder tweaks a schedule for a thicker gauge. Inspection data nudges tooling replacement before chatter appears. The result is not only fewer defects; it’s calmer production, because variability is caught upstream where it is cheaper to fix.

Safety, Skills, and Sustainability: People and Planet in the Machine Age

Great machines are only great when people go home safe and the planet’s tab doesn’t balloon. Safety starts in risk assessment—identifying pinch points, e-stops, stored energy, and the human-machine interface—then engineering hazards out. Interlocked guards, presence-sensing around dangerous motion, and dual-channel safety circuits are table stakes. Lockout/tagout procedures, clear sightlines, and fail-safe states prevent freak combinations of events from becoming incidents. Training seals the system: operators learn not just the button sequence but also the why behind limits and interlocks, so circumvention never feels like a shortcut.

Skills define the slope of your improvement curve. As machines absorb more judgment—sensing, adjusting, documenting—people climb toward diagnosis, optimization, and changeover wizardry. Microlearning, simulation, and side-by-side coaching shrink the time to proficiency. Cross-skilled teams reduce single-point failures when vacations, illnesses, or turnover hit. A pragmatic model pairs operators with maintenance on daily checks, giving each a shared language of vibration, temperature, and sound. The outcome is visible in cleaner starts, shorter recoveries, and fewer “we’ve always done it this way” blockers.

Sustainability ties into both ethics and economics. Energy-efficient motion profiles, idling policies, and right-sized motors trim kilowatt-hours. Compressed air audits close silent drains on power. Coolant management extends life and keeps disposal in check. Material choices and nesting strategies cut scrap, while remanufacturing and refurbishment keep assets in service longer, reducing capital and embodied energy. Environmental metrics must be tied to units shipped—grams of CO2e per good part—so victories don’t hide behind busy hours that produced little of value.

Trade-offs are real. Heavier guarding can slow access; slower feeds save tools but might risk the bottleneck. The answer is measured experiments:

– Pilot energy-intelligent recipes on one line; track energy per good unit.

– Test a quick-change guard that preserves safety integrity but speeds service.

– Compare two coolant strategies over a month with tool life and surface finish logged.

– Run a green time window where non-urgent machines idle, and watch if lead time suffers.

When safety, skills, and sustainability move together, the plant becomes calmer, more resilient, and easier to scale. That steadiness is what customers feel when deliveries are predictable and quality is quietly consistent.

Conclusion: Turning Machine Choices into Competitive Advantage

Industrial machines decide how fast you can move, how precisely you can hit spec, and how confidently you can promise dates. For manufacturers and operations leaders, the next step is practical: map your value stream to the real constraint, select machines that relieve it, and pair the investment with automation, maintenance, and data practices that ensure the gain sticks. Start small—a single cell with clear before-and-after metrics on OEE, scrap, energy per good unit, and changeover time. Build a short list of risks and mitigations, including safety interlocks, operator training, and a spare parts plan.

Choose technologies that fit your product mix and volume, not buzzwords. Subtractive, forming, molding, or additive all have a place; the right combination depends on tolerance, finish, and demand variability. Weave in the digital thread to reduce keystrokes and prevent recipe errors, and aim condition monitoring at the assets where a surprise hurts most. As you scale, keep culture in view—when teams trust the machines and the machines tell the truth through data, improvement compounds. The outcome is a factory that meets customer needs with steady quality and lead times, while using energy and materials wisely.